The health supplement industry has witnessed a significant transformation over the years, not only in the variety of products available but also in the manufacturing processes and quality assurance mechanisms that ensure the efficacy and safety of these products. With an increasing number of individuals turning to dietary supplements to support their overall health, manufacturers are now adopting innovative approaches to meet the demand for high-quality products. This article will delve into the latest advancements in supplement manufacturing and the rigorous quality assurance practices that are setting new standards in the industry.

Embracing Technology in Manufacturing

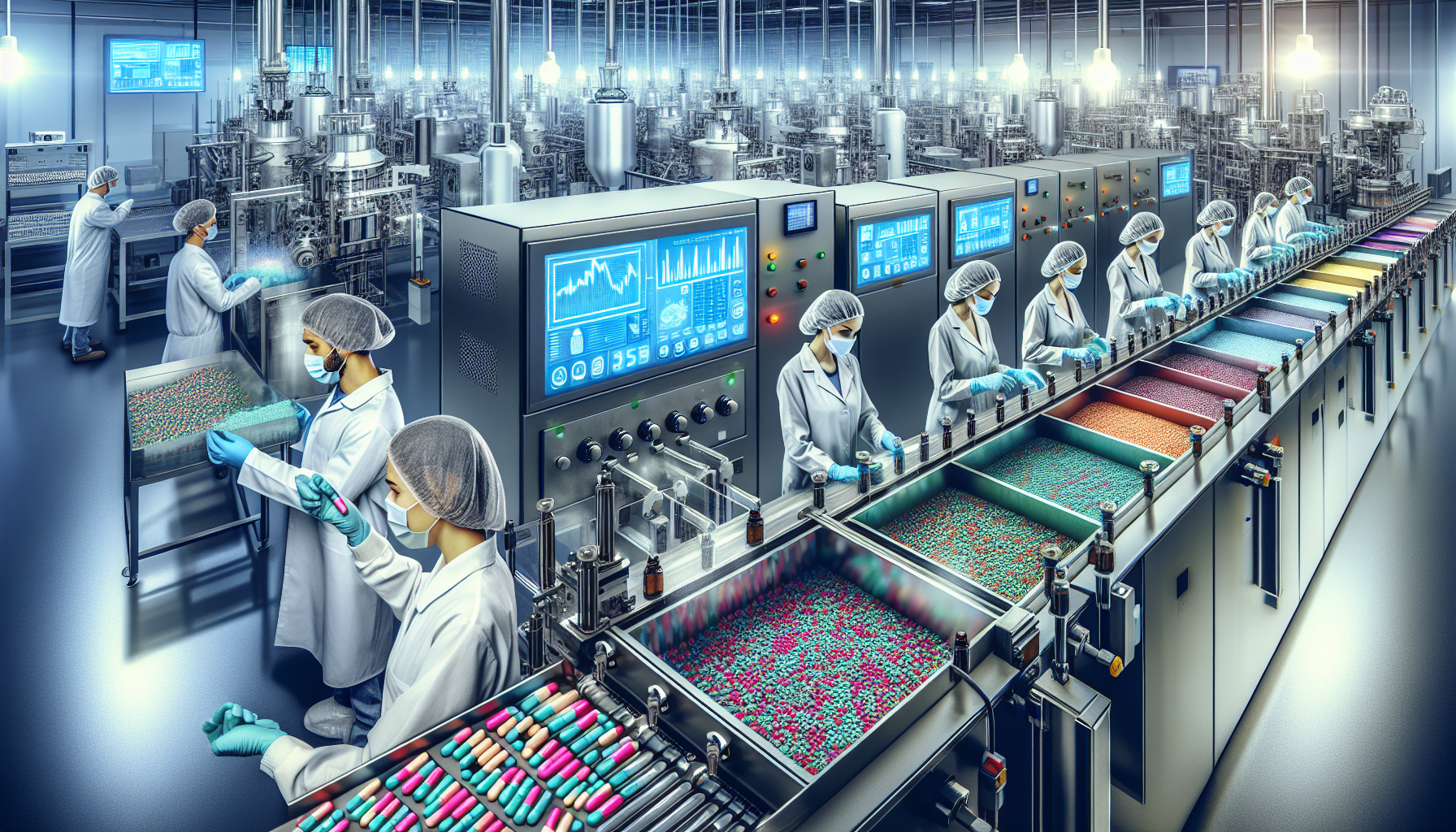

The advent of technology has been a game-changer in supplement manufacturing. State-of-the-art equipment and automation have replaced many manual processes, leading to increased efficiency, accuracy, and consistency in production. One of the key technological advancements is the use of high-speed encapsulation machines, which can produce thousands of capsules per hour while ensuring precise dosage. Moreover, digital monitoring systems are now commonplace in facilities, allowing for real-time tracking of production parameters and immediate correction of any deviations from set standards.

For those seeking to enhance their cardiovascular health, cutting-edge manufacturing techniques have led to the development of supplements that promote heart health with greater purity and potency.

Incorporating Artificial Intelligence

Artificial intelligence (AI) is proving to be a valuable asset in supplement production. AI algorithms can predict optimal ingredient combinations and concentrations, leading to the creation of more effective formulations. Additionally, AI can oversee quality control, identifying imperfections or contaminants that might go unnoticed by the human eye. This use of AI not only enhances the quality of supplements but also streamlines the entire manufacturing process.

Advanced Extraction Methods

The purity of the ingredients is paramount in the production of dietary supplements. Innovative extraction methods, such as supercritical CO2 extraction, have become more prevalent. This technique allows for the extraction of pure compounds without the use of harsh solvents, which can leave behind unwanted residues. The result is a cleaner and more potent supplement that consumers can trust.

Customized Solutions

Personalization has made its way into the supplement industry with manufacturers offering customized vitamin and nutrient mixes tailored to individual needs. By analyzing personal health data, companies can formulate supplements that address specific deficiencies or support particular health goals, such as immune support or digestive health.

Stringent Quality Assurance

Quality assurance is the backbone of supplement manufacturing. The industry has seen a shift towards more stringent testing protocols to ensure that products are free from contaminants and adulterants. High-performance liquid chromatography (HPLC) and mass spectrometry are two analytical techniques widely used to verify the purity and potency of ingredients, providing a level of scrutiny that was once unattainable.

Third-Party Certification

To further instill consumer confidence, many supplement manufacturers are now seeking third-party certifications from organizations such as NSF International or the United States Pharmacopeia (USP). These certifications validate that a product meets high standards for quality and safety. The process involves rigorous testing and regular facility audits, ensuring that manufacturers adhere to the best practices in production.

Sustainable Sourcing and Eco-Friendly Packaging

As consumers become more environmentally conscious, supplement companies are responding by implementing sustainable sourcing practices for their ingredients. This includes the use of organically grown herbs and non-GMO sources. Additionally, eco-friendly packaging solutions, such as biodegradable bottles and recyclable materials, are becoming more prevalent in the industry.

Regulatory Compliance

Regulatory compliance is critical in the supplement industry. Manufacturers must navigate a complex landscape of regulations to ensure their products are safe and legal to sell. This involves staying up-to-date with the guidelines set forth by the Food and Drug Administration (FDA) and other regulatory bodies. Compliance is not only a legal requirement but also a commitment to consumer safety.

For instance, understanding the role of medication and supplements in chronic disease management is crucial, as highlighted in the article "Chronic Disease Management: Optimizing Medication and Supplement Use."

Educating Consumers

Education plays a vital role in the supplement industry. Manufacturers are taking it upon themselves to inform consumers about the benefits and proper usage of their products. This includes providing detailed information on supplement labels, as seen in the article "Understanding Supplement Label Accuracy and Regulations."

Leveraging Technology for Consumer Engagement

In today’s digital age, supplement companies are leveraging technology to engage with consumers directly. Through social media, mobile apps, and interactive websites, companies can provide personalized recommendations, share educational content, and gather valuable feedback to continuously improve their products.

Future Directions

The supplement manufacturing industry is poised for further innovation. Research into bioavailability enhancement, such as the use of nanotechnology for improved nutrient absorption, is ongoing. Additionally, the exploration of novel ingredients, such as adaptogens and nootropics, is expanding the horizons of what supplements can offer.

The industry is also likely to see more collaboration with healthcare professionals, integrating supplements into comprehensive treatment plans, as discussed in "Patient-Centered Care: Considering Supplement Use in Treatment Plans."

Conclusion

The landscape of supplement manufacturing and quality assurance is continually evolving, driven by technological advancements and a commitment to meeting consumer demands for high-quality, safe, and effective products. By embracing innovative manufacturing techniques, stringent quality controls, and transparent consumer education, the industry is setting a new benchmark for excellence.

As consumers, it is important to stay informed and choose supplements from reputable manufacturers who invest in these innovative approaches. By doing so, individuals can confidently incorporate these health-supporting products into their wellness routines, knowing they are backed by the highest standards of production and quality assurance.

To further explore the intersection of supplements and health, readers can delve into articles such as "The Impact of Nutraceuticals on Health and Wellness" and "Nutritional Supplement Trends and Consumer Behaviors."

With continued innovation and a focus on quality, the future of supplement manufacturing looks bright, offering promising new ways to support health and well-being.

For more in-depth resources on supplement manufacturing and quality assurance, consider exploring: